Steinway is a well-known name that’s music to a lot of people’s ears in Queens, including Steinway Street, one of the borough’s main thoroughfares, and the nearby Steinway subway stop. But the factory that put that street on the map more quietly goes about the business of making some of the best pianos in the world just blocks away.

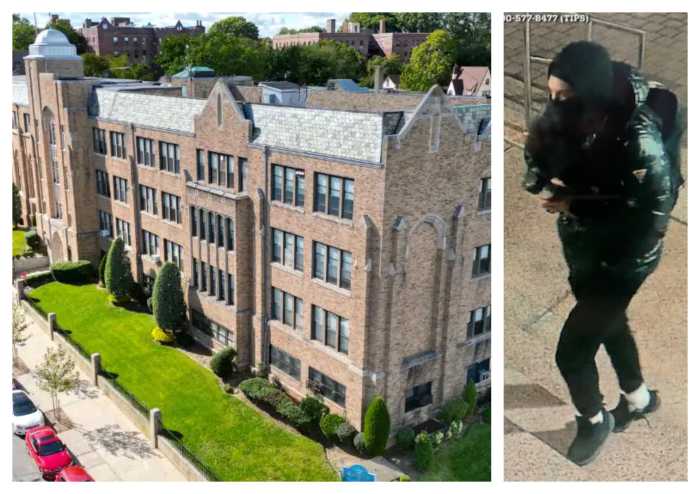

Hidden in plain sight in Astoria, Steinway & Sons, at 1 Steinway Pl., is a master piano maker and a factory filled with craftspeople making pianos and history for more than a century in a space that feels half like a museum and half like a factory.

It’s also a nearly 175-year success story and an example of manufacturing American style as well as sign of musical excellence in Queens. They have managed to succeed as a manufacturer in New York City at a time when manufacturing jobs often were shipped overseas and as electric keyboards caught on.

“It’s so mathematical. So much engineering went into this,” Cameron Underhill, wholesale operations and institutional support manager, said in the factory. “This is where you string the piano. The Steinway string scale is a low-tension scale, compared to other manufacturers, which contributes to Steinway’s depth of tone.”

Underhill stood in the factory filled with so many parts like puzzle pieces waiting to be assembled into premium pianos, where craft (along with care and commitment) and some tech is king.

“A lot of it is geometry. A lot of this was developed in the 1870s,” Underfill continued. “It’s been a hallmark of Steinway for 150 years plus.”

Steinway’s process involves a large amount of craftsmanship and handiwork, as well as machinery, using a pneumatic press, tuning pins, drills, CAD and software to produce, if not a perfect piano, a precious one.

“They route the string by hand. This is the bridge. It will go around this termination point and back down,” Underhill added. “It’s a very intentional process. We have between 220 to 240 strings on a piano. It depends on the model. It takes most of a day to string a piano.”

Although pride is intangible, it is a key element in the craft and the company, at once part of the pride of Queens and holding a prominent, enduring place in the heart of some of the world’s best musicians for over a century.

“I think that the legacy of craftsmanship is very obvious when you walk through this facility,” Underhill added in the large, nearly silent space where so much music starts. “And the pride in the craft and building the instrument to be used by the world’s top pianists.”

The Steinway secret

Standing in a room surrounded by beautiful pianos, Steinway’s Vice President of Marketing and Communications Anthony Gilroy looked at past, present and future.

“We try to keep a variety of sounds among these pianos. They are the same size, the same model, the same color,” Gilroy said. “They look identical. They all have their own sound personalities. They’re hand-crafted, made of wood.”

Some things have changed here and some have not for this company that balances machinery with craft, talent with technology. The Steinway property, once over 400 acres (including land used to build LaGuardia Airport), shrank to 11 and is now 5.5 acres.

“We do R and D, continuously working to improve,” Gilroy said of traditional computers as well as high-tech, player pianos, along with sound science and the science of sound. “They will test the piano, see how it works, get feedback. Sometimes, we get feedback from our top artists.”

With a keen business sense, Steinway also does limited editions, including 10 pianos designed by Lenny Kravitz that sold for $500,000 each. Most people who buy Steinways are “on the older side, 50 and over,” Gilroy said, noting younger customers also purchase their pianos.

“Even though we’re a traditional company, our advertising is very digital-focused,” Gilroy said. “We have a niche audience.”

The company trains sales representatives through what it calls William Steinway University, or WSU.

“They come to the factory for a couple of days, learn about the products, get the factory tour, learn about marketing,” Gilroy said of this factory, which is a kind of promised land for pianos. “It’s 2.5 very full days of classes. They get introduced to Steinway and its history.”

The company also owns the Boston and Essex piano brands, which are less expensive and not manufactured at the Steinway factory. In addition to honoring classical musicians, they work with and honor contemporary artists, such as Billy Joel.

“We hung his portrait in our previous Steinway Hall,” Gilroy said of their Manhattan store once at 57th Street. “He was the first non-classical musician to have his portrait hung.”

The Steinway story

To understand the Steinway story, you might wonder which “Steinway” family members started this all. Actually, Heinrich Engelhard Steinweg built pianos in Germany in the late 1830s through the late 1840s, before he and his family immigrated to New York in 1850, working for three years for other manufacturers.

“At the time, there were dozens and dozens of piano makers in New York and hundreds in the world,” Gilroy said. “The piano was the entertainment center of the home. It was everything rolled up into one.”

Steinweg Americanized his name, becoming Henry E. Steinway, founding Steinway & Sons in 1853 on Varick Street in Manhattan, before moving to their Astoria location about 150 years ago.

“They knew people couldn’t pronounce Steinweg,” Gilroy continued. “They Anglicized their name to Steinway.”

The company was good at innovating and finding ways to improve the piano, using single bent pieces of wood to make rims that are standard today. “We have a rim-bending section where they take long laminates of maple and bend it,” Gilroy said. “That was invented by the Steinways.”

They also developed overstringing, placing bass strings over the treble, creating a kind of sensation with the Steinway sound. High tech, then, was at the heart of this art from the start.

“They took this craft, innovated and brought it back to Europe,” Gilroy said. “It sounded so much different and better. It really was a mania. I liken it to when the iPhone first came out.”

Connecting the numbers

A lot has happened since then: Steinway has made about 630,000 pianos in its 170-plus years. In the Astoria factory, about 200 union employees, supported by 100 more in offices, make about four pianos a day.

The company annually makes a total of about 1,000 in New York and Hamburg, where it also operates a factory. Pianos made in the U.S.A. have markings indicating that, as well.

The Astoria factory occupies about 400,000 square feet and five floors, making pianos that contain thousands of parts. “It’s an 11-month process from start to finish. It takes almost a year,” Gilroy said. “There are over 10,000 parts in a piano, hundreds of distinct processes. There is conditioning time.”

A new Steinway grand can easily cost from $90,000 to $200,000, similar to the ones in Carnegie Hall.

“Many processes are by hand and some are machines with operators,” Gilroy added. “We hire a lot more computer scientists and engineers than 10 years ago. But we hire people who hand-chisel wood and people who work with their ears in tone regulation.”

New York City, Anthony said, provides not only history, but a workforce that lets Steinway continue its tradition.

“It’s one of the reasons we’re still in New York,” Gilroy said. “We have access to this great workforce willing to learn this as a trade.”

On a recent visit, someone was retiring after more than 50 years, since starting in 1973. “I know that because I was born in February of ’73,” Gilroy said. “She was here working when I was born.

The sound board

Steinway employs craftspeople who often have spent decades delicately building pianos designed to produce rich sound.

“Look at all this wood-working. It’s done with dowels and no screws,” Gilroy said. “The braces are necessary to withstand the string tension.”

Many Steinway workers have been with the company for a big chunk of their life, such as Jagdesh Sukhu, a Queens resident and soundboard specialist at Steinway since 1987.

“It’s good employment and a great job,” Sukhu said as he made soundboards. “Everything is specific. You have to be correct at the spot.”

Steinway, he said, has about 140 patents as part of the process, including innovations with the soundboard. “To get the best music, you have to have the best soundboard,” Sukhu said.

Steinway worked with acoustic scientists when acoustic science was new, improving technology, such as soundboards, Gilroy said. They knew this was about science, not just sound, knowledge, not just craft.

“They realized they were studying sound waves. Things like our scales, the angles of the overstrings. We had assistance in figuring it all out,” Gilroy said. “So the strings underneath vibrate in harmony with the strings over them.”

They bring the base strings over the heart of the soundboard to create what Sukhu calls a “thundering base.”

“Any engineering change is a major thing, but it’s not something we’re afraid of,” Gilroy added, noting they have made changes over the years. “We don’t fear change. We just want to make sure change is going to improve the piano.”

Sukhu talked about what he was doing before discussing the company and craft, making pianos sound and look good.

“It’s very important. There’s a lot of stuff here, a lot of operations on this board,” Sukhu added before going back to work. “I’m doing cosmetics to the board.”

While Sukhu works with pianos during the day, at home he sometimes enjoys playing the instrument. “I have a Steinway at home, an upright,” he added. “I play some songs. I love music.”

The sound of success

You might wonder what all the fuss and fame are really about. While these pianos are beautiful, they are, of course, all about not just the bass, but the treble clef and the signature sound of Steinway.

“When you play a good piano, it makes a huge difference,” said Charles Berg, who works at a Steinway store in Arkansas. “A good pianist will sound great on a good piano.”

A Steinway that’s tuned and taken care of really can make a big difference for a pianist and an audience, he said.

“There’s the access to different kinds of tone on a well-maintained Steinway,” Berg continued. “When you play a Steinway like that, you have less things that limit you artistically.”

Berg, who said he played his last piano recital at a Methodist church in Bellavista, Arkansas, said Steinways can make pianists sound better.

“With a pianist, you usually play whatever’s in front of you,” Berg said. “If you have to adjust to your piano, you’re limited as to how soft you can play. The Steinways that I have played, the recent ones and the ones here, give me that room.”

Sound future

There are many famous Steinways, including one that Cole Porter used to compose in the Waldorf Astoria and which Steinway restored. “The Cole Porter piano is there. It was in his room in the Waldorf Astoria,” Gilroy said. “He wrote many songs on that piano.”

They also restored a Steinway for the Motown Museum in Detroit that had been in the Motown Studios. The factory is suffused by a sense of history, although they hope at some point to create a museum in the factory. LaGuardia Community College houses the Steinway collection with documents, letters, old advertisements and more.

The company owns 18 showrooms or stores nationwide in places such as Los Angeles, San Francisco, Seattle, Chicago, Miami, Philadelphia and New York City. Digital is getting better, but Steinway still offers something special.

“There always will be a desire for acoustic, just like with guitars,” Gilroy said. “Someone would get rid of a stencil, grind down a logo on a plate and try to pass it off as a Steinway.”

Steinways are made in the United States and Europe, but those sold in the United States typically are made here. “We lean into Made in the USA,” Gilroy said. “Even though we have the two factories, we primarily build the pianos for the American market here.”

He sees Steinways as works of technology and art, at once adapting to the times and remaining true to the spirit with which Steinway started.

“The precision of a Swiss watch in a much bigger footprint, they have a lot of moving parts,” Gilroy said when asked to describe a Steinway. “We are looked at as the best and a luxury product. If we tried to build our piano to a price point, we couldn’t do it here. We try to make everybody compete with us on quality, which they can’t.”