The recent failure of a CFM engine on a Southwest Jet has raised concern over the safety of jet engines. There are calls from politicians to do a better job in inspecting aircraft engines. Inspecting engines can begin with one of the graduates from the Aviation High School here in NY and at JFK Airport.

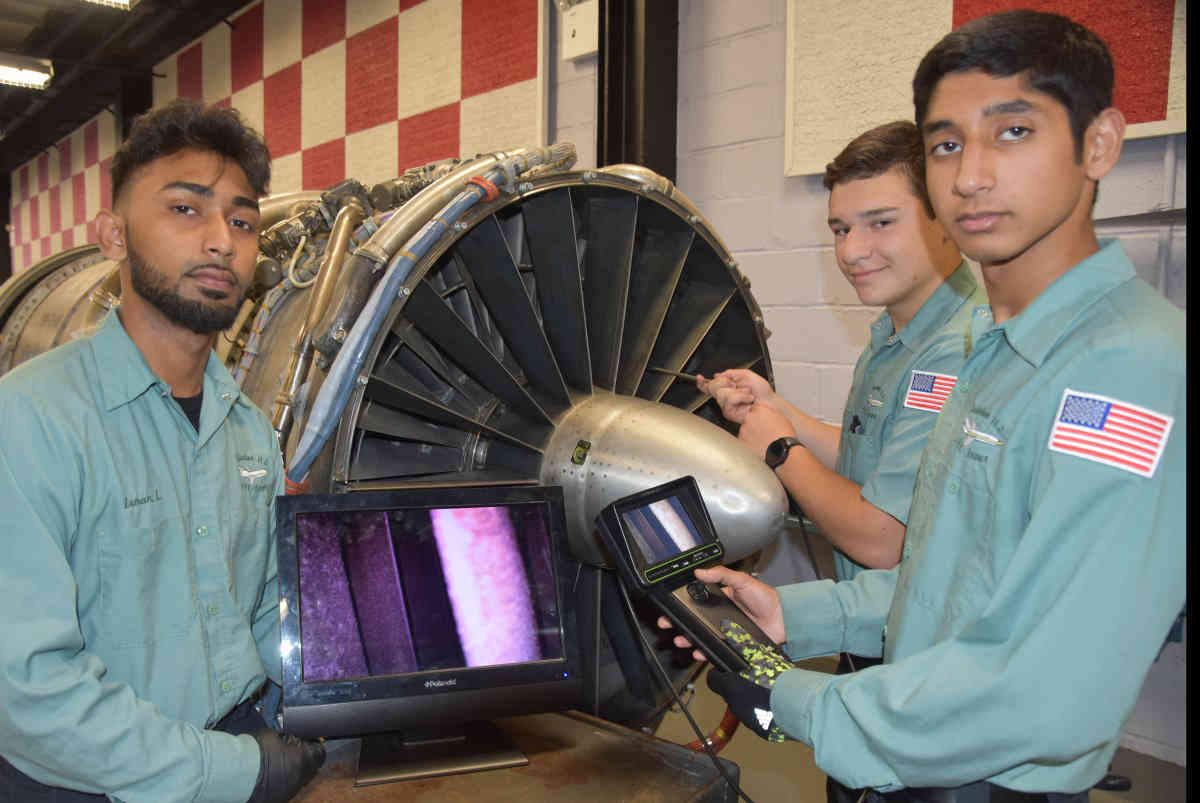

The Aviation High School (AHS) Annex at JFK Airport trains students for a career in aviation mechanics. At their facility they learn how to inspect aircraft engines with a variety of instruments. One is the borescope which is an endoscopy type camera which can penetrate the inner areas of an engine and show details of parts such as chips, corrosion or other conditions. If this inspection indicates damage, then the engine goes to further inspection with ultrasound or X-rays.

Ultrasound can detect early stages of metal fatigue which is suspected as a reason for the Southwest engine failure aeccor1ding to NTSB‘s preliminary report. According to one airline mechanic, there can be a manufacturer defect or every so tiny fissure which is not evident during normal inspections. Airlines have scheduled inspections that increase in detail as the flying hours accumulate. Inspections vary from straight visuals, borescopes, fluorescent dyes, ultrasound and x-rays are all tools used to look for problems either as indicted or according to service timetables.

FAA has determined that the recent CFM engine issue is not a systemic problem. The FAA had recommended more intensive inspections following a 2016 engine issue. Previously proposed mandatory inspections to implement x-ray type/ultrasonic views of fan blades and engine components , but were not enacted that would have move the mandate beyond the proposal stage.. A service bulletin first year issued a recommendation to perform such inspections but was not mandated. Now however, airlines are inspecting more than just CFM engines for signs of metal fatigue.

According to industry reports, the CFM56 is the best selling jet engine in the world and used by Airbus on its A320, A321 and on aircraft on many American carriers as well as the military “Doomsday Plane” used as a back up for the President.

As a result of the recent engine failure, the engine manufacture joint venture between General Electric and French Safran, many airline operators

are increasing inspections coinciding with European regulators ordered checks on some 737’s. Southwest said it is speeding up inspection on all related engines in its fleet within 30 days. Their entire fleet is made of up Boeing 737 aircraft. According to an instructor at the AHS, taking each fan blade off and performing an ultrasonic inspection on each blade is extremely time consuming but will likely be done for the safety of the flying public.

The website Aviation DB lists all commercial aircraft repairs to any part of the aircraft. There is no mention nor listing of any engine issue related to this Southwest aircraft. The last service date was recently in December 2017on this specific CFM series turbine air generator engine.

As one knowledgeable industry man said, “ These are all well manufactured and maintained equipment. Something like a grain of sand could present a problem.”

So, the public waits for a final determination and report from the NTSB which will help prevent future accidents and give the maintenance and repair people greater guidance for inspections.